Technology

How does Auto Cure work?

Auto Cure’s software application and robotic hardware were designed by growers to allow a wide range of settings for drying, curing, and storing your harvest.

Auto Cure Specs

Auto Cure is an airtight curing environment which uses laminar air flow dynamics to vent relative humidity in cycles according to the humidity of your harvested cannabis flower.

Hardware

- 7” LCD Touchscreen Display

- Ventilation Fans

- Heavy-duty Venting Servos

- Laboratory-Grade Acrylic

Software

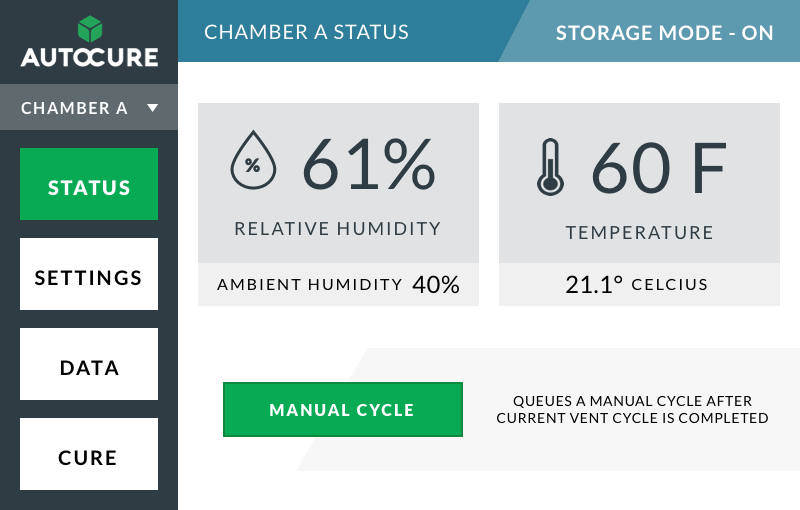

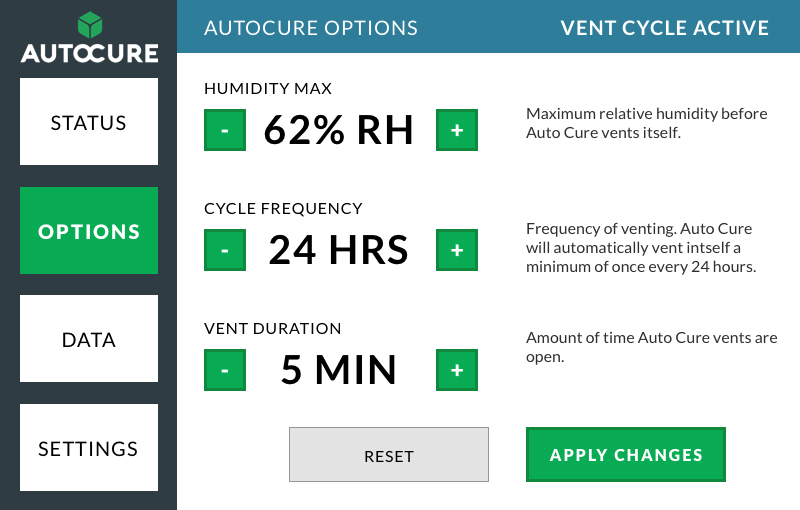

Auto Cure software regulates unit temperature and relative humidity automatically, taking the guesswork out of curing. An easy-to-use interface allows further control over vent cycles and maximum humidity.

Automated Vent Cycling

Auto Cure can be set to vent at a RH% Max Threshold determined by the user, once every X hours, or manually. Curing data is tracked in real-time and logged in Auto Cure Cloud.

Airflow Dynamics

Auto Cure utilizes laminar air flow dynamics during automated venting cycles to create a completely uniform air pathway so that all flowers within the chamber are drying and curing at the same rate. Laminar air flow (bottom to top, side to side) via negative pressure guarantees that all saturated air contents are released from the unit and new fresh air is evenly distributed.

Airtight Curing

Proper curing must be executed in an airtight environment, separate from ambient humidity conditions and external factors. Conventional humidity controlled drying rooms subject harvested material to ambient RH%, resulting in evaporation and desiccation on one hand, or over-saturation and mold on the other.

How Vapor Pressure and Vapor Pressure Deficit Affect the Drying & Curing of Cannabis

The definition of Vapor Pressure is the equilibrium pressure of the vapor above the sample (solid or liquid) at a given temperature. In cannabis curing, vapor pressure indicates the the moisture release above the cannabis flower or leaf as evaporation and the pressure it exerts at equilibrium.

Equilibrium occurs when evaporation equalizes in an enclosed system at a particular temperature and air pressure. In general, the lower the vapor pressure is, the higher the rate of evaporation will be.

Vapor Pressure Deficit (VPD) is an indicator of the evaporation potential of the water to the air. This measurement describes the difference, or deficit, between the pressure exerted by the moisture present in the air and the pressure at saturation (equilibrium).

VPD is typically inversely related to RH and VP. A high VPD is associated with a low RH and VP, and a low VPD is associated with a high RH and VP.

The Vapor Pressure Differential is the difference between low and high VP in two controlled chambers. Ideally, the VP should be consistent and contained within an enclosed system until a controlled mechanism allows passage betwen chambers.

When drying and curing cannabis, we desire a high VPD for the intake air into the sealed chamber and a medium VPD inside the chamber for proper control of the drying and curing process.

Learn more about VPD at Grower’s Network.

Auto Cure is the first machine that properly cures your harvest automatically with multiple sizing options for both commercial and personal applications.

The Auto Cure Story

Auto Cure is the first machine that properly cures your harvest automatically with multiple sizing options for both commercial and personal applications.

Long gone are the days in which countless hours were spent perfecting the process of your harvest, only to have loss and waste occur during the final step. Whether the curing buds are accidentally neglected, allowing for mold spores to reproduce in conditions that are too humid, or over-dried due to excessive handling, proper curing techniques are paramount to producing a final product that consistently earns top-shelf value, as well as eliminating unnecessary waste and labor expenses. Both of these variables contribute directly to your bottom line, in addition to the general efficiency of your growing process as a whole.

View on Instagram

View on Instagram

Optimal Curing

Common knowledge indicates that curing is essentially a secondary drying process that is done at a slower rate than hang-drying in order to bring the finished product to a desired level of relative humidity (RH%), without destroying valuable terpenes and oils.

However, what is often overlooked is that true curing must be executed in an air-tight environment that is separate from ambient humidity conditions. This allows the harvested material to mature in an environment that will not dry the product too fast and stay mold free, if the air within the curing environment is vented (burped) at the right time. Keeping that in mind, extended drying rooms and other humidity controlled environments are not exact curing methods as the product is constantly subject to ambient RH%. The result can lead to evaporation and desiccation on one hand, or over-saturation and mold on the other - if not tended with increasingly watchful eyes.

A Controlled Environment

Auto Cure was meticulously designed and engineered over a two-year period in order to address all of the issues previously mentioned involved in the curing process and consolidates the solutions into a single machine.

- Auto Cure's air tight curing chamber is fabricated from laboratory grade acrylic which produces no off-gassing and is welded together without the use of glues and/or adhesives.

- Stainless steel latches pull tight a rubber-lined door for easy access and to create an air-sealed internal environment.

- Within the chamber, two fixed sensors take readings of both RH% and Temperature which are displayed on the 7” LCD touchscreen mounted on the control panel above the cure-chamber.

- On the posterior of the unit, two separate flow chambers for intake and exhaust house two servos and four fans which turn on/off in order to create/stop the ventilation of fresh air into the cure-chamber, while removing all humid air which is created from the slow evaporation of moisture from inside the buds.

View on Instagram

View on Instagram

Laminar Airflow Dynamics

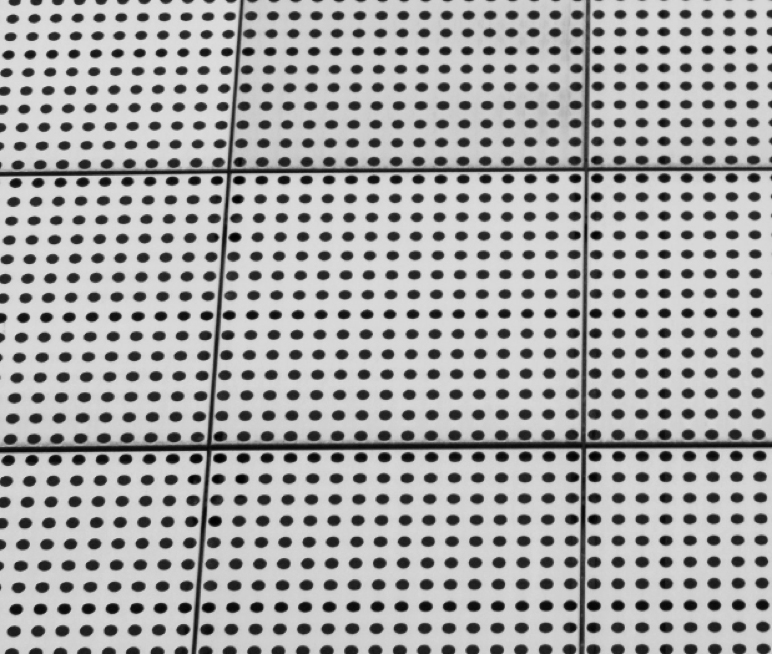

Auto Cure's air-flow dynamics are what set the device apart from any other type of curing method invented. First, the machine's holding trays are perforated with over two-thousand holes in each of the respective bases in order to ensure complete and uniform airflow throughout the chamber. Auto Cure utilizes laminar air flow dynamics (bottom to top, side to side) via negative pressure to guarantee that all saturated air contents are released from the unit and new fresh air is evenly distributed. Additionally, dust filters are installed onto the intake and exhaust holes of the unit to ensure that the contents remain in pristine condition.

The Only Automated Solution

Auto Cure is self-monitoring and self-adjusting through the constant vigilance of its custom designed software application which is displayed on the 7” Touchscreen mounted on the top of the unit. To use Auto Cure, simply set the humidity max, cycle frequency, and vent duration, and let the machine handle the rest.

Auto Cure can be set to vent via a Time Max Threshold (cycle frequency - once every “X” number of hours) and a RH% Max Threshold (once sensor readings reach user-set RH%) for automated curing cycles. It is also programmed with a Manual Cycle feature that allows the user to vent the machine at will.

Last but certainly not least, all curing data generated from Auto Cure's vent cycles are logged to a secured online portal which customers are able to access via www.cloud.autocure.us once a username and password are submitted.

View on Instagram

View on Instagram

Efficiency & Return on Investment

Auto Cure is truly one of the most innovative and cost-effective products to be introduced into the growing industry in recent memory, and will improve the efficiency of your grow process. In addition to cost savings analysis and increased sales value, Auto Cure produces a legitimate return on investment (ROI) within the first two cycles of usage, so you will be assured that your investment in Auto Cure will be paid back multiple times over.

Ready to learn more?

We'd love to talk to you about our technology and how AutoCure can help you grow your business - literally.

Contact Us