Return on Investment

There are five areas that Auto Cure technology addresses to reduce cost and/or increase profitability.

1

Minimize Labor Expense

Auto Cure automates the drying and curing process — eliminating virtually all labor associated with the manual burping process. Go straight from freshly harvested to packaging with top-shelf results, all without touching the flower.

Whether your operation cures product using plastic buckets, turkey bags, or some other method, the labor required to manually burp containers is costly and time consuming. Additionally, the decision on when to burp the containers is dependent on a master grower with many years of experience curing various strains of cannabis.

In Auto Cure's Minimum Effective Airflow environment, the maximum RH% inside the Auto Cure chamber is set by the cultivator. When that threshold is reached, two sets of fans — one that exhausts the moist atmosphere in the chamber and one that introduces new drier ambient air into the chamber — are set in motion. The differential in the two atmospheres is what facilitates a true curing process. Auto Cure's Minimum Effective Airflow environment provides the optimum environment for the flower to release its moisture without outside interference. This level of expert curing does not require guesswork or years of experience.

2

Reduced Drying & Curing Time

Auto Cure substantially reduces the time from harvest to perfectly cured product, typically 4-7 days fewer than traditional curing methods.

3

Eliminate Waste Due to Mold

Auto Cure's patent pending software and robotics monitor the system at all times, controlling maximum humidity levels and venting out excess moisture when thresholds are reached inside the chamber. This dynamic process effectively eliminates the potential for mold growth.

Auto Cure’s venting process leaves no dead zones or micro climates, evenly distributing ambient airflow across the chamber and throughout the product. With shorter curing time, product has less possibility of developing mold spores, reducing or eliminating mold waste entirely.

4

Maintain Product Consistency

Product run through Auto Cure maintains consistent top-shelf quality, allowing for brand recognition and the ability to properly forecast harvests.

Auto Cure logs each and every cure allowing the cultivator to enter qualitative and quantitative information including lab test results. Past cure data can be compared and cures repeated to produce desirable strain characteristics.

5

Higher Selling Price

Cannabis consumers highly value product consistency and are willing to pay a premium for higher-quality flower and lab-tested products, increasing sales price by at least 10%.

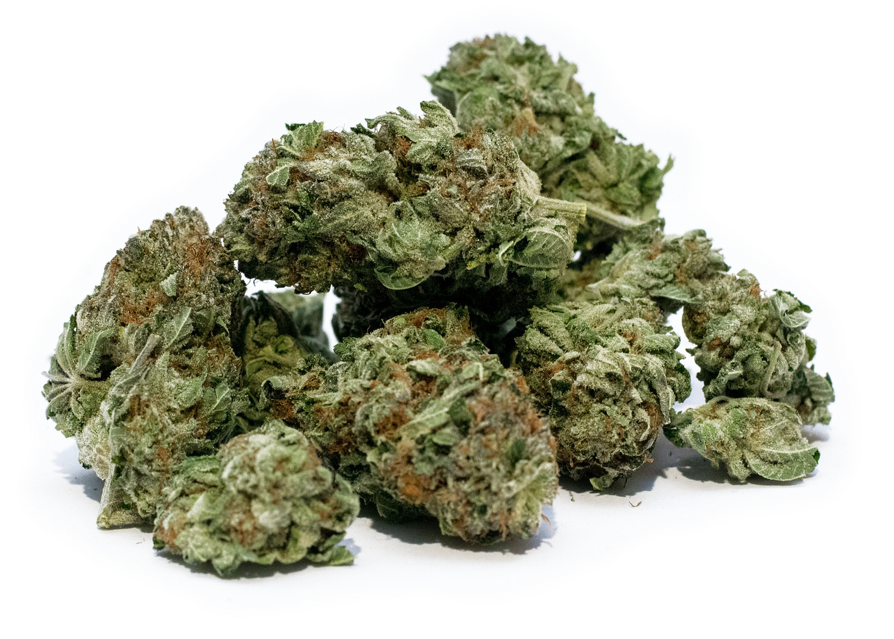

Product produced by Auto Cure retains more trichomes due to less handling during the curing process, giving it a frosty appearance. Better appearance and better nose demand a higher selling price.

Cannabis consumers highly value product consistency and are willing to pay a premium for higher-quality flower and lab-tested products, increasing sales price by at least 10%. Lab results verify higher total active cannabinoid and terpene concentration compared to traditional curing methods. A 5% increase in wholesale product price gives a full 100% ROI in 1-3 curing cycles depending on Auto Cure unit size.